Nanografi provides an end-to-end security architecture, ranging from the secure, integrated facilities established for the defense sector to the advanced security inks developed for identity and document protection. Ahead of TRUSTECH 2025, we spoke with Business Development Fatmanur Taş about how the company’s high-security production experience forms the essential foundation for its trusted ink technologies.

Q: For those who may not know Nanografi yet, could you give us an overview of the company and its core mission?

Nanografi started as one of Türkiye’s pioneering nanotechnology companies and has grown into a global supplier of advanced materials and specialty chemical solutions. Today, we export to over a hundred countries and collaborate with research centers, governmental institutions, defense organizations, and high-tech and defense industries worldwide. Our expertise covers advanced materials, inks, energy, and smart technologies for industrial, security, and defense applications. At the heart of Nanografi lies a simple mission: to make scientific innovation accessible and applicable to real-world industrial, defense, and security challenges.

Q: You will represent Nanografi at TRUSTECH 2025. What brings the company to this major event for authentication and secure printing?

TRUSTECH is the global meeting point for professionals in payment, identification, and digital security. For us, it is the ideal platform to demonstrate how Nanografi’s advanced security inks can redefine the standards of document authentication, identity protection, and brand security. We aim to connect with partners who value both scientific precision and industrial scalability; the two principles that guide our ink production and development. Our attendance highlights how our broader security know-how, including experience with secure production in sensitive defense-related environments, supports the absolute consistency and trustworthiness of these high-security inks.

Q: “Security inks” is a term we often hear in relation to document protection, but what does it mean in Nanografi’s context?

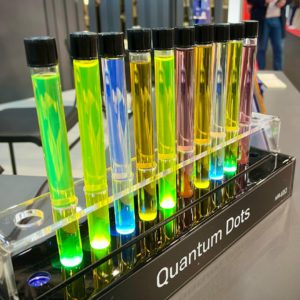

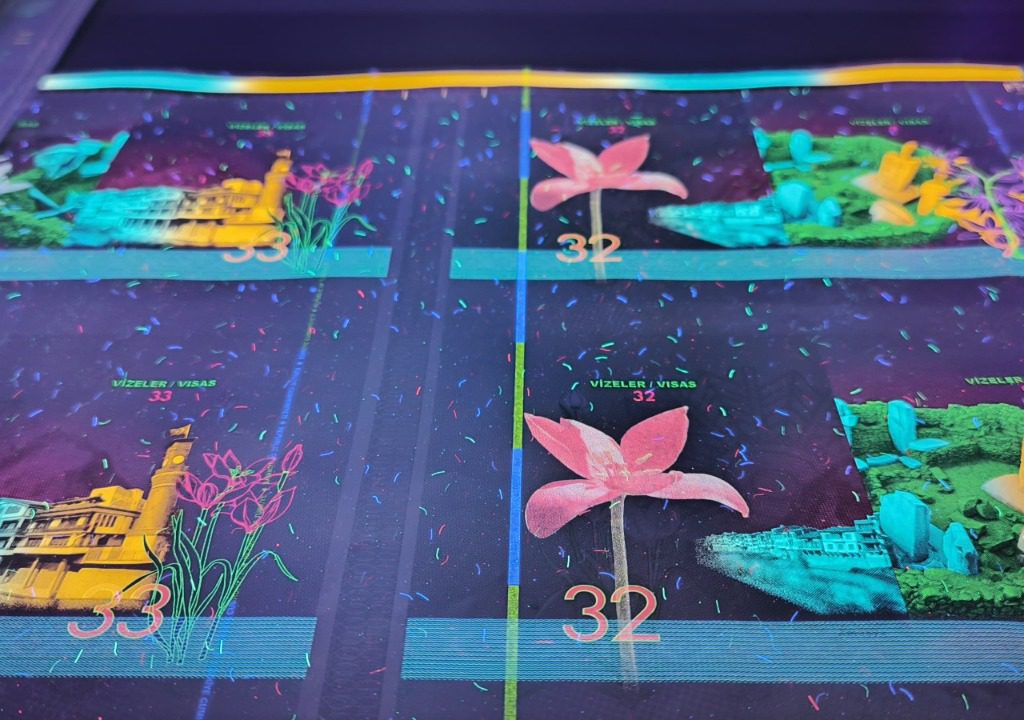

Security inks are highly engineered formulations that go beyond color; they are designed to resist forgery, counterfeiting, and duplication. Our inks operate on multiple layers of security, combining visible, invisible, and machine-readable features. At Nanografi, we develop a wide range of products including UV, IR, multi-fluorescent, and optically variable inks tailored to each customer’s protection level. Some inks are reactive under specific wavelengths; others contain proprietary taggants for unique traceability. The goal is to make every document, label, or product uniquely verifiable.

Q: What global challenges do security inks address, and how does Nanografi contribute to solving them?

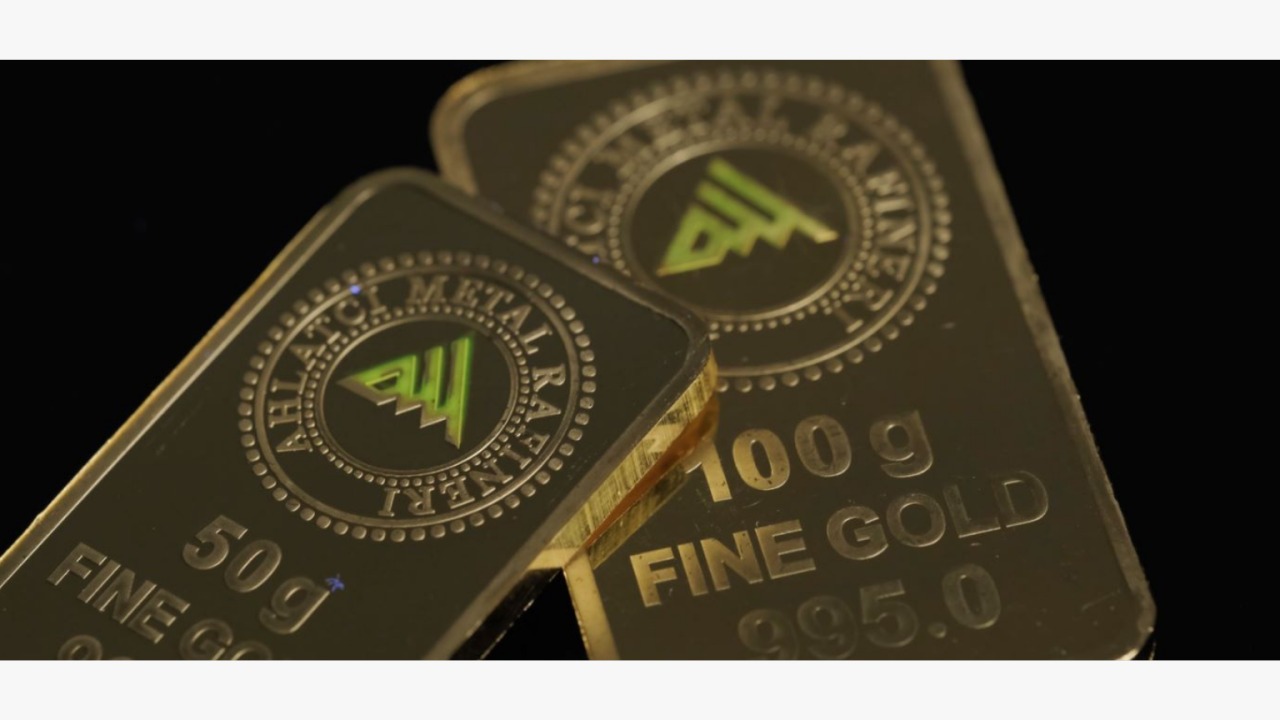

Counterfeiting has evolved dramatically with the rise of high-resolution printing and digital reproduction tools. Governments, banks, and global brands face increasing risks; from forged identity cards and passports to fake product labels and certificates. Security inks form the first line of defense. When integrated properly, they expose tampering attempts immediately, whether through UV–IR reactivity, optical shifts, or hidden taggants. Nanografi’s contribution is offering advanced formulations that are designed to remain stable and long-lasting, which is key for official documents, financial instruments, and, importantly, defense and governmental identity applications.

Q: Nanografi has established integrated secure-production facilities for sensitive sectors, including defense. How does this experience influence your work in security inks?

Our integrated secure-production facilities designed for the defense sector go far beyond standard controlled manufacturing environments. They are purpose-built for developing highly sensitive, verifiable, and traceable security components.

This mindset is crucial for our ink business. When you produce security inks, you are dealing with formulas that must not be replicated or leaked. Our experience, which includes working with high-security processes like gunpowder manufacturing and complex chemical synthesis, means we adhere to the strictest standards for restricted access, process documentation, and high traceability. This ensures that when a security printer or a government institution works with us, they are not only buying a technically advanced ink; they are also benefiting from a production process shaped by a background in high-security, defense-level projects, guaranteeing an unparalleled level of assurance and integrity.

Q: How does Nanografi differentiate itself in this specialized field, combining scientific depth with security standards?

What sets Nanografi apart is our ability to combine scientific depth with the rigorous discipline of our secure production environment. We are not just a manufacturer; we are a technology-driven organization with strong R&D foundations. This enables our laboratories to custom-design inks based on specific wavelength responses or printing substrates, offering true bespoke security solutions. Furthermore, our in-house quality control ensures every batch meets international security and durability standards. In short, our competitive edge is defined by innovation, precision, and the guarantee of a production reliability that mirrors defense sector expectations.

Q: Who do you hope to connect with at TRUSTECH 2025?

Identity document issuers, secure printers, and public institutions are a natural fit. We are also keen to meet partners in brand protection and traceability – from packaging and luxury goods to electronics. Crucially, we expect to speak with representatives from sectors where document and data integrity are absolutely critical, including certain areas of defense and governmental operations. TRUSTECH lets us co-design projects, aligning our pigments and inks with each partner’s threat model and production realities.

Q: Finally, how would you summarize Nanografi’s approach to security for our readers?

We see security as something that has to be engineered at multiple levels – the chemistry of the ink itself, and the ultra-secure environment in which that ink is conceived, produced, and delivered. Nanografi’s approach is to bring these elements together. Our work in advanced materials, our experience in setting up integrated secure production facilities, and our focus on high-performance security inks all support the same goal: giving institutions and companies tools they can rely on when trust has to be protected, not assumed. TRUSTECH 2025 is a critical platform for us to understand how science can shape the future of authentication.

Q: Thank you for the conversation, Fatmanur. Any final thoughts?

Thank you for the opportunity. It’s always inspiring to share how science and collaboration can reinforce the very concept of trust. We look forward to welcoming everyone at TRUSTECH 2025 and exploring how innovation can continue to make the world a more secure place.